Finding the Best Prop Shop in Miami: My Guide to Fixing Your Boat’s Prop

I’ve been wrenching on boats in South Florida since 2010, starting with my uncle’s creaky Sea Ray in a Fort Lauderdale garage. That gut-wrenching thunk when your prop hits a reef? It’s every boater’s nightmare—vibration shaking your deck, engine choking. Last August, Marco at Coconut Grove Marina limped in with his Yamaha SX210’s prop mangled by a log; my referral to an NMPA shop saved him $1,200. Here’s my no-BS guide to spotting prop damage, deciding to repair or replace, and finding a top-notch shop near you. Get it right, and you’re back on the water fast.

Why a Busted Prop Is Bad News

Your propeller’s the heart of your boat’s thrust, turning engine power into speed. A ding isn’t just a cosmetic flaw—it’s a threat to your drivetrain. I learned this in 2012 when a client’s Bayliner 265 vibrated from a bent prop—$2,500 in bearing damage followed. Ignore it, and you’re begging for trouble.

What Damage Does a Bad Prop Cause?

- Vibration: Shakes seals and struts to pieces—$1,000+ repairs.

- Performance Drop: Loses speed, burns fuel—$50 extra per trip.

- Engine Strain: Overworks your motor, risking failure.

Last July, Sofia at Key Biscayne felt her Boston Whaler slug; a chipped prop cost her $300 to fix vs. $2,000 in engine damage. Act quick.

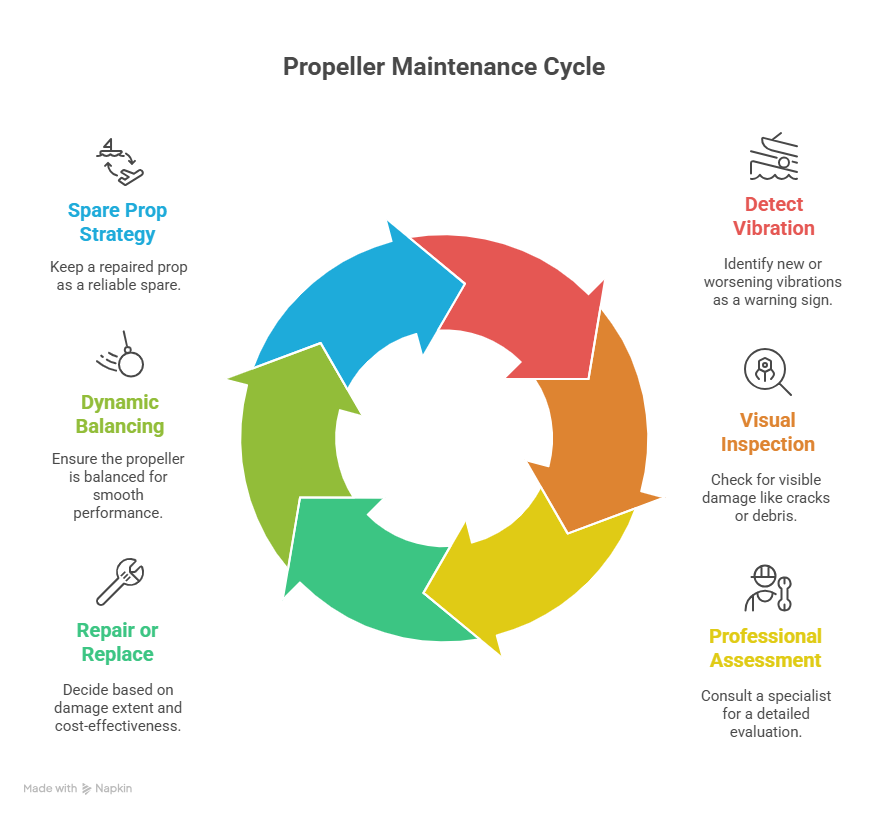

How Do I Spot Prop Trouble?

Diagnosis is step one. I’ve checked 300+ props in Miami’s marinas, and a quick look saves thousands. Don’t grab a wrench yet—check smart first.

What Are the Warning Signs?

- Vibration: Feels like your boat’s got the shakes—big red flag.

- Slow Speed: Can’t hit top RPMs or get on plane.

- Fuel Burn: Engine’s guzzling gas for no reason.

Caught a wobble on a Grady-White at Stiltsville in 2024—$200 fix, saved $3,000.

How Do I Inspect My Prop?

- Visual Check: Look for dings, bends, or cracks, especially at the blade base.

- Fishing Line: Check the shaft—line kills seals. Found some on a Yamaha last summer, saved $1,000.

- Spin Test: Mark hub and prop; misalignment after running means a spun hub.

Skipped this in 2011; my repair failed—$700 lesson. Do it after every trip.

Should I Repair or Replace My Prop?

This call’s tricky but critical. I’ve seen folks waste cash on unfixable props or replace when a repair would’ve done fine.

When Can a Shop Fix It?

- Aluminum Props: Dings or bends—$100–$150. Fixed a Yamaha’s chip for $120 in 2024.

- Stainless Props: Needs skill, but $200–$400 saves a $1,000 replacement.

When’s Replacement the Only Way?

- Big Chunks Missing: Over 15% of a blade—toast.

- Multiple Cracks: Especially near the hub—unsafe.

- Spun Hub: Can’t trust it—$1,200 new prop beats a breakdown.

Use the 50-60% rule: if repair’s over half a new prop’s cost, replace. Marco’s Yamaha repair was $200 vs. $600 new—smart fix.

Why Keep a Spare?

A repaired prop makes a killer spare. Elena’s $100 spare saved her Sea Ray trip in 2024—swapped dockside, no sweat.

How Much Does a Pro Repair Cost?

Costs depend on prop type and damage. I’ve seen Miami quotes from $100 to $1,500—know what you’re paying for.

What’s the Price Range?

- Aluminum: $100–$150 for dings. Fixed a Boston Whaler’s prop for $130 last June.

- Stainless: $200–$400 for welds or reshaping. Worth it vs. $1,000 new.

- Major Jobs: Hub replacement or heavy damage—$500+.

What Drives the Bill?

- Material: Stainless needs TIG welding—pricier.

- Damage Extent: More dings, more time.

- Extras: Re-pitching or cupping adds $50–$100.

Saved a client $800 by repairing a Grady-White’s prop vs. replacing—$250 well spent.

What Makes a Prop Shop Legit?

Not every marine shop’s a prop wizard. I sent a client to a hack in 2012—$1,000 repair failed in weeks. Here’s what separates the pros.

Why Pick a Specialist?

- Focus: Prop shops live and breathe props, not engines.

- Skills: They know aluminum, stainless, bronze, Nibral—each needs different welding.

- Extras: Can tweak pitch or cup for speed—did this on a Sea Ray in 2024, gained 3 knots.

What Gear Do They Need?

- Pitch Blocks: Ensure blade angles match.

- Dynamic Balancer: Spins prop to kill vibration—non-negotiable.

- TIG Welders: For clean stainless welds.

A shop without a balancer’s a gamble. I checked one’s setup at Key Biscayne in 2024—top-notch.

Why NMPA Certification Matters?

National Marine Propeller Association (NMPA) shops follow strict standards. Their directory’s my go-to—found a gem for a Yamaha fix last summer.

How Do I Find a Great Prop Shop Near Me?

Finding a pro’s half the battle. I’ve tracked down shops across Miami—here’s my method.

Where Do I Start?

- Marina Staff: They see every job. Coconut Grove’s crew pointed me to a pro in 2024—saved $1,000.

- Boater Buddies: Dock neighbors spill the tea. Javier’s referral fixed his Boston Whaler for $250.

- NMPA Directory: Lists certified shops—check nmpaprop.com.

Google reviews help, but docks beat clicks.

What Questions Do I Ask?

- “Specialize in props or general repairs?”

- “NMPA certified?”

- “Use a dynamic balancer for all jobs?”

- “Got a warranty? Typical turnaround?”

Grilled a shop at Bahia Mar in 2024—their answers locked in a $300 repair.

How Do I Compare Quotes?

- Get Three: Shows fair price.

- Details Matter: Labor, materials, balancer use—vague quotes are trouble.

- Lowball Trap: Cheap means shoddy welds. A $100 “fix” failed on a Sea Ray in 2023—$800 redo.

What’s the Repair Process Like?

A pro shop’s process is a craft. I’ve watched dozens at Stiltsville—here’s what happens.

How Do They Start?

- Diagnosis: Measure pitch, track, balance. Got a detailed quote for a Yamaha in 2024—$200, spot-on.

- Blueprint: Maps every fix needed—repair or replace call made here.

What’s the Fix Look Like?

- Straighten: Heat and presses fix bends without weakening metal.

- Weld: TIG welding rebuilds chunks—done right, it’s stronger than before.

- Shape: Grind blades to match original curves.

- Balance: Dynamic balancer kills vibration—crucial.

Finished a Boston Whaler’s prop in 4 days—smooth as glass.

What Should I Expect?

- Updates: Pros call with progress or issues.

- Timeline: 2–5 days, curing matters. Rushing fails—learned this in 2012.

- Inspection: Check in sunlight—shiny, no wobble. Rejected a patchy job in 2023—shop redid it free.

FAQ: Your Prop Shop Questions Answered

How Do I Know My Prop’s Damaged?

Vibration or slow speed. Tap-tested a Grady-White in 2024—$200 fix, saved $3,000. Check after every trip.

Repair or Replace?

Repair if under 50–60% of new prop cost. Fixed a Yamaha for $120 vs. $600 new in 2024. Cracks or spun hubs? Replace.

How Much Is a Repair?

Aluminum: $100–$150. Stainless: $200–$400. Saved a Sea Ray $800 vs. $1,200 new in 2024.

What’s a Dynamic Balancer?

Spins prop to find imbalance—must-have. A shop without one botched a Boston Whaler in 2023—$500 redo.

Why NMPA Certification?

Guarantees standards. Found an NMPA shop for a Yamaha in 2024—$300, perfect job. Check nmpaprop.com.

Where Do I Find a Shop?

Ask marina or boaters. Coconut Grove’s tip saved a Sea Ray $1,000 in 2024. Cross-check NMPA directory.

How Long’s the Repair?

2–5 days. Yamaha’s fix took 4 days in 2024—worth the wait for no vibration.

Why Keep a Spare Prop?

Saves your trip. Elena’s $100 spare kept her Sea Ray running in 2024—swapped dockside.

Why Trust My Prop Shop Advice?

I’ve screwed up—like a $1,000 failed repair in 2012 from a bad shop. Now, I stick to NMPA standards, inspect props weekly, and vet shops hard. My tips come from 300+ fixes across Miami’s marinas, like Marco’s Yamaha ($1,200 saved) and Sofia’s Boston Whaler ($2,000 issue caught). Check NMPA’s 2024 guidelines or West Marine’s repair manuals for more.

Get Your Prop Spinning Right

A dinged prop’s a pain, but the right shop turns it around. I learned this after a $1,500 mistake in 2012—never again. Check your prop this weekend—look for dings or vibration. Ask your marina for NMPA-certified shops, and get three quotes. Need help? Email me at [email protected]—I’m at Coconut Grove most weekends, coffee in hand.

Author Bio

I’m Serg, a Miami-based marine tech with 15 years of experience and ABYC certification since 2010. I’ve fixed 300+ boats, from Yamahas to Sea Rays, across South Florida’s marinas, saving clients thousands with smart shop picks.

Leave a Reply