Quick Answer

Inboard Engine Rebuild Cost. The cost of an inboard engine rebuild can vary significantly depending on the extent of the damage and the specific components that need attention. Minor repairs can range from $300 to $1,000, while major overhauls can cost anywhere from $1,500 to $6,000 or more. Factors such as engine size, brand, and labor rates can also impact the overall cost. In some cases, replacing the engine may be a more cost-effective solution, with prices ranging from $5,000 to $20,000 for a new inboard engine.

[BUTTON: Get free estimates for Inboard Engine Rebuild now]

Introduction

As a boat owner, determining whether to repair or replace your inboard engine can be a complex and costly decision. The inboard engine rebuild cost can vary widely depending on the extent of the damage and the specific components that need attention. Understanding these costs is essential for making an informed decision that aligns with your boating needs and budget. This guide will help you navigate the factors that influence inboard engine rebuild costs and provide insights to help you make the best choice for your vessel.

Lower Unit Repair Cost: What to Expect for Repairs and Replacements

Transom Repair: Mastering Fixes for Aluminum, Fiberglass and Wooden Boats

Frequently Asked Questions

1. How much does an inboard engine rebuild cost?

The cost of an inboard engine rebuild can vary significantly depending on the specific repairs needed. Here are some typical costs:

| Service Type | Average Cost | Price Range |

|---|---|---|

| Water Pump Replacement | $300 – $800 | $250 – $1,000 |

| Carburetor Rebuild | $400 – $800 | $300 – $1,000 |

| Cylinder Head Overhaul | $1,500 – $3,000 | $1,000 – $4,000 |

| Engine Block Rebuild | $3,000 – $6,000 | $2,000 – $8,000 |

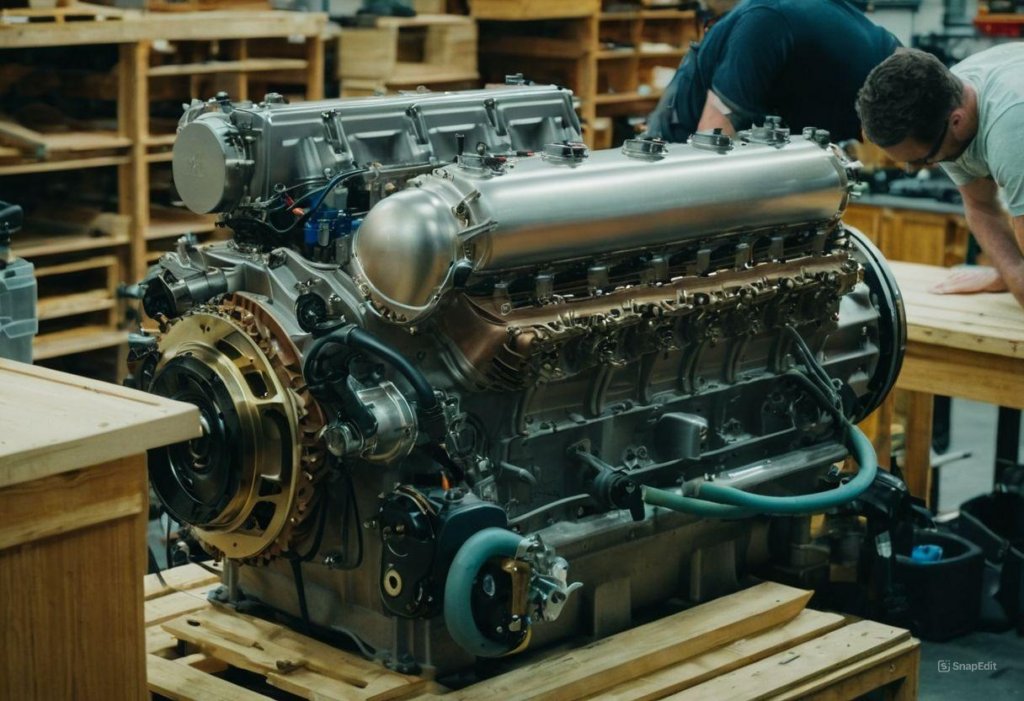

2. What factors affect inboard engine rebuild costs?

Several key factors can influence the inboard engine rebuild cost:

- Engine Size and Complexity: Larger and more complex engines typically require more extensive work, resulting in higher costs.

- Brand and Age: Newer engines and premium brands tend to be more expensive to rebuild than older or discontinued models.

- Extent of Damage: The severity of the damage will significantly impact the overall rebuild costs.

- Labor Rates: Labor costs can vary based on the repair facility’s location and the technicians’ expertise.

3. Is it better to rebuild or replace an inboard engine?

The decision to rebuild or replace an inboard engine depends on several factors:

- Age and Condition of the Engine: If the engine is relatively new and the damage is minor, a rebuild may be the most cost-effective solution.

- Projected Repair Costs: If the rebuild costs are approaching the price of a new engine, replacement may be the better option.

- Desired Performance and Reliability: A new engine can provide improved performance, efficiency, and reliability compared to a rebuilt engine.

- Future Boating Plans: Consider your intended usage and how long you plan to keep the boat when deciding between a rebuild and replacement.

4. How can I save money on an inboard engine rebuild?

Here are some tips to help save money on an inboard engine rebuild:

- Perform Regular Maintenance: Regular inspections and maintenance can help prevent costly repairs down the line.

- Consider DIY Repairs: If you have the necessary skills, some minor repairs can be done yourself to save on labor costs.

- Shop Around for Quotes: Compare prices from different repair facilities to find the best deal.

- Use Quality Parts: Investing in quality parts can save you money in the long run by reducing the frequency of repairs.

5. How often should I rebuild my inboard engine?

The frequency of inboard engine rebuilds depends on several factors, including the engine’s usage, maintenance history, and the manufacturer’s recommendations. As a general guideline, most inboard engines should be rebuilt every 1,000 to 2,000 hours of operation or every 5 to 10 years, whichever comes first. However, it’s always best to consult with a qualified marine technician or the engine manufacturer for specific guidance on your engine model.

Money-Saving Tips

- Perform Regular Maintenance: Keeping up with routine maintenance can prevent costly repairs down the line.

- Consider DIY Repairs: For those with mechanical skills, tackling minor repairs can save on labor costs.

- Shop Around for Parts: Compare prices from various suppliers to find the best deals on parts.

- Maintain Proper Storage and Care: Proper storage and care of your boat can help prevent inboard engine issues.

- Stay Informed: Keep up with the latest maintenance tips and best practices for your inboard engine.

[BUTTON: Find Inboard Engine Rebuild Services near you]

Additional Resources

- Outboard Service Cost: What to Expect and How to Save

- 4 Stroke Outboard Maintenance: A Visual Guide

- Outboard Service Near Me: Understanding Costs and Maintenance

Conclusion

Understanding inboard engine rebuild costs and the factors that influence them is essential for maintaining your boat’s performance and reliability. By being proactive about maintenance, staying informed about common issues, and exploring cost-saving strategies, you can ensure your inboard engine remains in top condition for years to come. Remember, addressing inboard engine problems promptly can save you from costly repairs and ensure a smooth boating experience.

[BUTTON: Get free quotes from Inboard Engine Rebuild Professionals now]