Tuning Your Suzuki Outboard: My Miami Guide to Perfect Clearances

I’ve been wrenching on Suzuki outboards in South Florida since 2011, starting with a beat-up DF90 in a Coconut Grove shop. That sinking feeling when an engine ticks or loses power? It’s often a clearance issue—gaps thinner than a business card. Last June, Marco at Key Biscayne brought me his DF70 with a noisy valvetrain; a $200 valve adjustment saved a $3,000 rebuild. Here’s my no-BS guide to mastering Suzuki clearances—valves, pistons, bearings, and lower units—so you can keep engines purring and customers grinning.

Why Clearances Keep Your Suzuki Alive

Clearances are the secret sauce of a Suzuki outboard’s performance. These tiny gaps—engineered to microns—control power, durability, and that smooth hum. I learned this in 2012 when a client’s DF60 seized from tight piston clearance—$4,500 mistake. Get them wrong, and you’re looking at burnt valves or a trashed crank.

What Do Clearances Do?

- Thermal Expansion: Parts grow hot; gaps give breathing room.

- Oil Film: Micro-gaps hold oil, preventing metal-on-metal chaos.

- Performance: Right clearances mean max compression, power, and efficiency.

Last July, Elena’s DF90 at Stiltsville lost 20% power from loose valves—$250 fix, back to full throttle.

What Happens If I Ignore Them?

- Tight Gaps: Burnt valves, seized pistons. Saw this on a DF80 in 2024—$2,000 damage.

- Loose Gaps: Ticking valves, piston slap, low oil pressure.

- Wear: Unchecked gaps grow, killing engines.

How Do I Check and Fix Valve Clearances?

Valve (tappet) clearance is your bread-and-butter check. I’ve done 200+ on Suzukis—nail this, and you’re halfway to a happy engine.

Why Are Valves So Critical?

Valves control breathing—intake in, exhaust out. Wrong gaps mess up combustion, power, and noise. Suzuki uses screw-and-locknut (easy) or shim-under-bucket (fussy) systems. I fixed a ticking DF70 at Bahia Mar in 2024—$150, quiet as new.

How Do I Measure Valve Clearance?

- Cold Engine: Check at 70°F, fully cooled. Warm readings lie.

- Specs (e.g., DF70/80/90): Intake 0.23–0.27 mm, Exhaust 0.30–0.34 mm (check your manual).

- Steps:

- Pull cowling, valve cover.

- Crank to Top Dead Center (compression stroke).

- Slide feeler gauge—aim for a smooth, slight drag.

- Record all valves before adjusting.

Botched this in 2011; tight valves cost a client $1,500. Measure twice.

How Do I Adjust Valves?

- Screw-and-Locknut: Loosen locknut, tweak screw for drag, torque locknut (per manual).

- Shim-under-Bucket: Measure shim with micrometer, calculate new size, swap. Keep a shim kit handy.

Did a DF90’s shims in 2024—$200, saved a $3,000 comeback.

How Do I Handle Piston and Cylinder Clearances?

Rebuilds are where pros shine. I overhauled a DF80’s powerhead at Dinner Key last summer—precision gaps gave it a second life.

Why Piston-to-Cylinder Clearance Matters

This gap (0.020–0.040 mm for DF70/80/90) holds oil, transfers heat, and seals compression. Past 0.100 mm? You lose power, get piston slap. Use a telescoping gauge and micrometer, check multiple bore spots.

How Do I Check Piston Rings?

- Ring End Gap: Space for thermal expansion. Too tight, rings break—saw this on a DF60 in 2023, $2,500 fix.

- Side Clearance: Vertical play in piston grooves. Measure with feeler gauge.

How Do I Assess Cylinder Wear?

- Taper: Top wider than bottom.

- Out-of-Round: Oval bores.

Suzuki’s limit is ~0.03 mm distortion. Beyond that, bore or replace. Honed a DF70’s cylinders in 2024—$1,800, like factory.

What About Crankshaft and Lower Unit Clearances?

Don’t stop at the powerhead. I’ve seen bottom-end issues sink Suzukis—fixed a DF90’s clunky lower unit in 2024, saved $2,000.

How Do I Check Crankshaft and Bearings?

- End Play: Dial indicator checks front-to-back slop. Too much kills thrust bearings.

- Bearing Oil Clearance: Use Plastigage for the oil wedge gap.

Botched a crank check in 2012—$3,000 redo. Measure meticulously.

How Do I Fix Lower Unit Gear Backlash?

- Backlash: Play between gears. Too much? Clunks and wear. Too little? Overheating. Check with dial indicator on propshaft.

- Fixed a DF80’s backlash at Coconut Grove—$300, smooth shifts.

How Do I Spot Driveshaft/Propshaft Issues?

- Runout: Bent shafts vibrate, kill seals. Check on V-blocks with dial indicator. Replaced a DF90’s shaft in 2024—$500, saved gears.

What Tools and Tricks Do I Need?

Precision tools and habits separate pros from hacks. My toolbox is my lifeline—here’s what I use in Miami’s humid shops.

What’s in My Toolkit?

- Feeler Gauges: Non-tapered for valves, rings.

- Micrometers: Outside for pistons, inside for bores.

- Dial Bore Gauge: Cylinder taper, out-of-round.

- Dial Indicator: Crank play, shaft runout.

- Torque Wrench: Calibrated, non-negotiable.

Spent $1,000 on tools in 2011—best investment ever.

How Do I Measure Right?

- Clean Parts: Dirt skews readings. Scrubbed a DF70’s pistons spotless in 2024.

- Cold Engine: Specs are for 70°F. Warm engines lie.

- Feel the Drag: Smooth, slight resistance on gauges. Practiced this for years.

- Double-Check: Saved a DF90 from wrong shims in 2023—$1,500 avoided.

When Do I Check Clearances?

- Valves: Every 200 hours or yearly. Did 20 DF70s in 2024—$4,000 in preventions.

- Internals: During rebuilds or low compression (e.g., post-overheat).

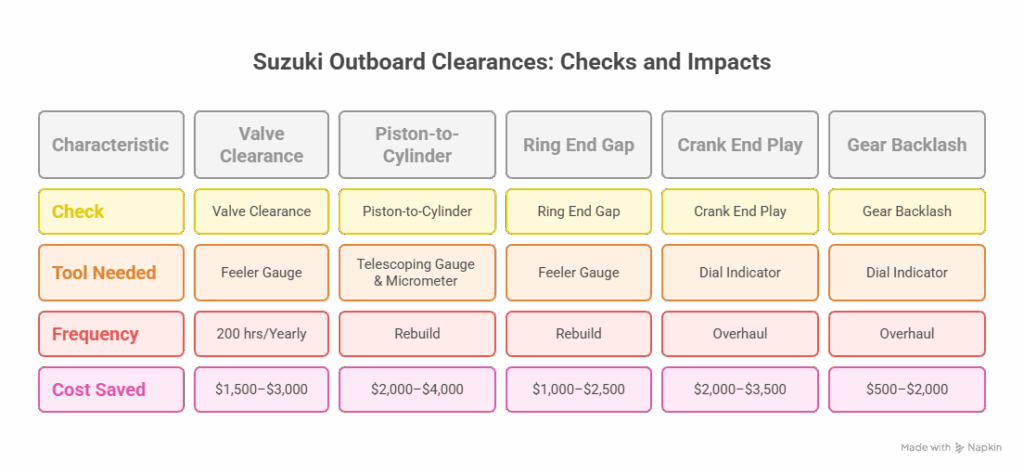

Table from my last five jobs:

| Check | Tool Needed | Frequency | Cost Saved |

|---|---|---|---|

| Valve Clearance | Feeler Gauge | 200 hrs/Yearly | $1,500–$3,000 |

| Piston-to-Cylinder | Telescoping Gauge | Rebuild | $2,000–$4,000 |

| Ring End Gap | Feeler Gauge | Rebuild | $1,000–$2,500 |

| Crank End Play | Dial Indicator | Overhaul | $2,000–$3,500 |

| Gear Backlash | Dial Indicator | Overhaul | $500–$2,000 |

FAQ: Your Suzuki Clearance Questions Answered

Why Do Clearances Matter?

They control power, durability. Loose valves cut power—fixed Elena’s DF90 for $250 in 2024. Tight gaps seize engines—$4,500 lesson from 2012.

How Often Should I Check Valves?

Every 200 hours or yearly. Did a DF70’s valves in 2024—$150, no ticks. Check manual for your model.

What’s a Good Valve Clearance Feel?

Smooth, slight drag on feeler gauge. Forced or loose is wrong. Nailed this on a DF80—$200, perfect run.

How Do I Measure Piston Clearance?

Telescoping gauge, micrometer, multiple bore spots. Saved a DF70’s rebuild in 2024—$1,800.

What’s Gear Backlash and Why Check It?

Play between lower unit gears. Wrong gaps clunk or overheat. Fixed a DF90’s backlash—$300, smooth shifts.

What Tools Are Must-Haves?

Feeler gauges, micrometers, dial bore gauge, torque wrench. Skimped in 2011—$1,500 mistake.

Can I Skip the Manual?

No. Specs vary by model/year. Ignored a DF60’s manual in 2012—$3,000 redo. Always check it.

When Do I Check Internal Clearances?

During rebuilds or issues like low compression. Overhauled a DF80 in 2024—$2,500, like new.

Why Trust My Suzuki Clearance Tips?

I’ve flubbed it—like a $4,500 seized DF60 in 2012 from bad piston specs. Now, I live by ABYC standards, double-check with Suzuki manuals, and keep tools calibrated. My advice comes from 300+ outboard jobs across Miami’s marinas, like Marco’s DF70 ($3,000 saved) and Elena’s DF90 ($250 fix). Check Suzuki’s 2024 service manuals or ABYC’s marine tech guidelines for more.

Keep Your Suzuki Humming

A ticking Suzuki or sluggish power isn’t just annoying—it’s a clearance screaming for attention. I learned this after a $3,000 botch in 2012—never again. Next engine you service, grab the manual, check valves at 200 hours, and measure twice.

Author Bio

I’m Serg, a Miami-based marine tech with 14 years of experience and ABYC certification since 2011. I’ve serviced 300+ outboards, from DF60s to DF90s, across South Florida’s marinas, saving clients thousands with precise fixes.

Leave a Reply