I’ll never forget a call I got a few years back. A family was stranded a few miles off of Key Biscayne. Their engine had just died. No warning, no sputter, just silence. When I got to them, the owner was panicked. “It just stopped,” he said, completely helpless. He had no idea what to even look at. Turns out, a corroded battery cable terminal had failed, cutting all power. It was a five-minute fix with a wire brush and a wrench, but for him, it was a day-ruining, tow-requiring disaster.

That experience taught me something important: a basic understanding of marine engine components isn’t just for mechanics. It’s one of the most powerful tools a boater can have. It turns panic into a plan. It helps you spot small problems before they become big ones and allows you to have an intelligent conversation with your mechanic, which saves you time and money.

This isn’t about turning you into a certified technician overnight. It’s about demystifying that big, loud thing in the middle of your boat. We’re going to break it down, system by system, in plain English. My goal is to give you the confidence that comes from a solid understanding of marine engine components, so you’re never that person stranded and helpless on the water.

Table of Contents

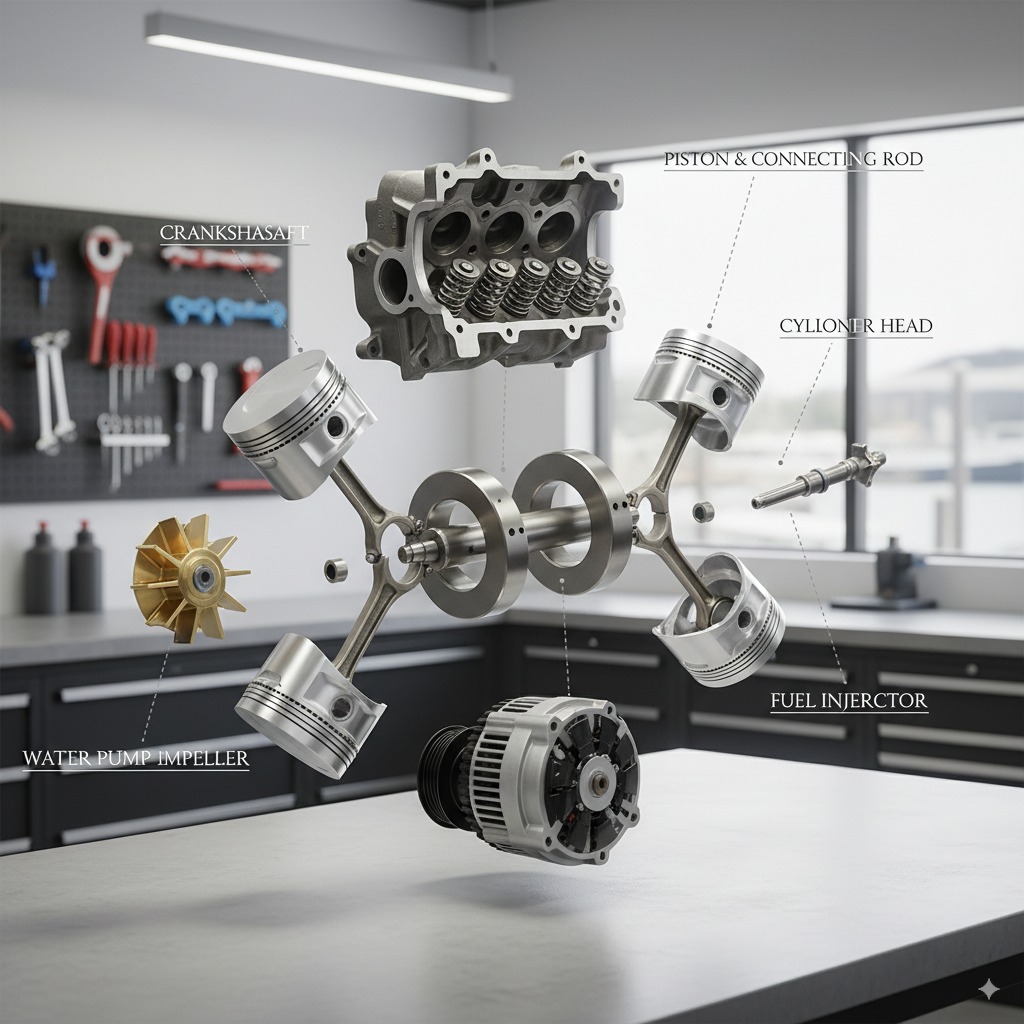

The Heart of the Matter: The Engine Block and Head

Everything starts here. Think of the engine block as the foundation and frame of your engine. It’s a heavy, solid piece of metal (usually cast iron or aluminum) that houses the cylinders, where all the magic happens. Inside those cylinders, the pistons fly up and down, driven by the explosive force of ignited fuel.

Bolted to the top of the block is the cylinder head. This is where you’ll find the valves that let air and fuel in and exhaust out, as well as the spark plugs that light the fire. The seal between the block and the head is critical, and it’s maintained by the head gasket. A failed head gasket is a major problem that can cause a whole host of issues, from overheating to catastrophic engine failure. A core part of understanding marine engine components is appreciating how these core parts work together.

The Lifeblood: The Fuel and Lubrication Systems

The Fuel System

No fuel, no fire. It’s that simple. But getting fuel from your tank to the engine is a journey with several key stops. A clear understanding of marine engine components in this system can solve 80% of common engine problems.

- Fuel Tank & Lines: This is where it all starts. Fuel lines can crack and leak, and tanks can accumulate water and debris.

- Fuel Filters: These are your engine’s last line of defense against dirt and water. A clogged filter will starve your engine of fuel, causing it to lose power or die. I tell my clients to change them religiously.

- Fuel Pump: This is what moves the fuel from the tank to the engine. It can be mechanical or electric. If it fails, your engine is dead in the water.

- Carburetor/Injectors: These are responsible for mixing the fuel with air in the precise ratio needed for combustion. Dirty carbs or clogged injectors are a top cause of rough running.

The Lubrication System

If fuel is the food, oil is the lifeblood. The lubrication system keeps all those fast-moving metal parts from grinding themselves into oblivion.

- Oil Pan (Sump): This is the reservoir at the bottom of the engine that holds the oil.

- Oil Pump: It circulates the oil under pressure throughout the engine.

- Oil Filter: Just like the fuel filter, this removes contaminants from the oil. A clean oil filter is essential for a healthy engine.

Ignoring the lubrication system is the fastest way to destroy your engine. That’s why a fundamental understanding of marine engine components includes knowing how vital clean oil is.

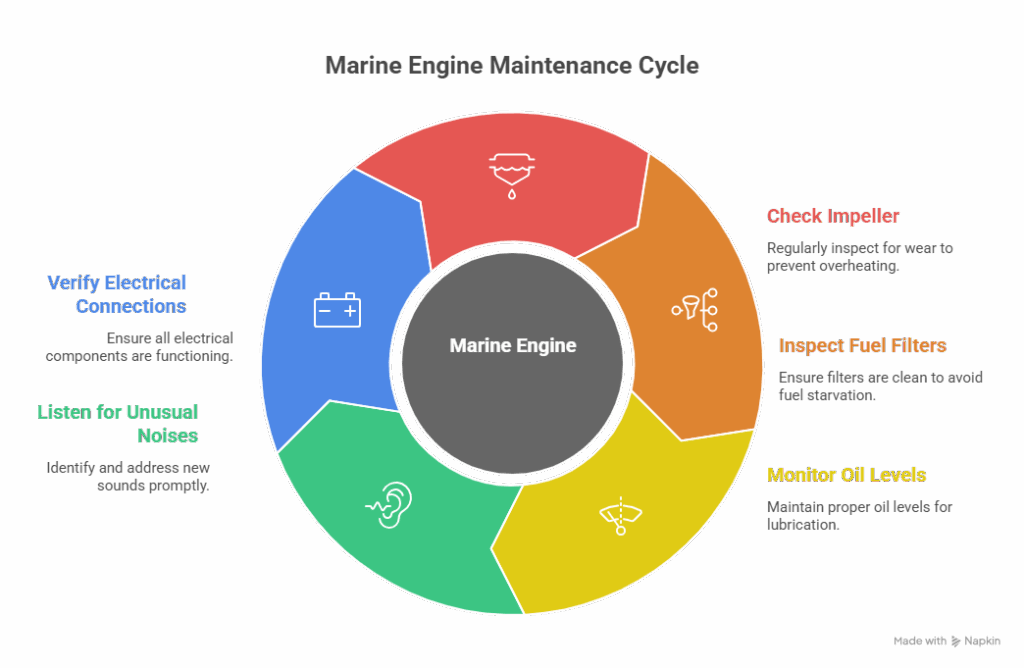

Staying Cool and Energized: Cooling and Electrical Systems

The Cooling System

Marine engines generate a massive amount of heat, and the cooling system is what keeps them from melting down. There are two main types: raw water cooling (which uses the water the boat is in) and closed cooling (which works more like a car’s radiator system).

- Water Pump & Impeller: The heart of the cooling system. The rubber impeller is a wear item that needs to be replaced regularly. A failed impeller is the #1 cause of overheating I see.

- Thermostat: This regulates the engine’s temperature, just like in your car. A stuck thermostat can cause the engine to overheat or run too cool.

- Heat Exchanger (on closed systems): This is like the engine’s radiator, using raw water to cool the engine’s internal coolant.

The Electrical System

This is the nervous system of your engine. A solid understanding of marine engine components here is crucial for reliability.

- Battery: Provides the power to start the engine and run electronics when the engine is off.

- Alternator: This is driven by the engine and recharges the battery while the engine is running.

- Starter: A powerful electric motor that turns the engine over to get it started.

- Ignition System (Coils, Spark Plugs): This creates the high-voltage spark that ignites the fuel.

Key Engine Components at a Glance

| Component | System | Function | Common Failure Sign |

|---|---|---|---|

| Pistons | Block | Compress air/fuel and transfer energy | Loss of compression, smoke |

| Fuel Filter | Fuel | Removes debris from fuel | Loss of power, stalling |

| Impeller | Cooling | Pumps raw water to cool engine | Overheating, no water from exhaust |

| Oil Pump | Lubrication | Circulates oil under pressure | Low oil pressure warning, noise |

| Alternator | Electrical | Recharges the battery | Battery not charging, warning light |

| Starter | Electrical | Cranks the engine to start | Engine won’t turn over, clicking |

FAQ: Questions I Hear All the Time

What’s the most important component for me to check regularly?

The impeller and your fuel filters. A failed impeller will kill your engine with heat, and a clogged fuel filter will leave you stranded. Checking these should be part of your routine. A solid understanding of marine engine components starts with these two.

Why is my engine making a new noise?

New noises are your engine talking to you. It’s telling you something has changed. A grinding could be a bearing, a squeal could be a belt, a ticking could be a valve. Don’t ignore it. Try to isolate where it’s coming from.

What’s the difference between a carburetor and a fuel injector?

Think of a carburetor as an “analog” fuel mixer and fuel injectors as “digital.” Carburetors are simpler but less precise. Fuel injectors are controlled by a computer and deliver a much more accurate fuel spray, leading to better efficiency and performance. Understanding marine engine components like these helps in diagnosing performance issues.

My engine won’t start, but it cranks. What’s the first thing to check?

The “kill switch” lanyard. I know it sounds dumb, but I’ve made more than one service call where the only problem was that the lanyard was pulled. After that, check for fuel and spark. It’s almost always one of the two.

How can an understanding of marine engine components save me money?

Simple. It lets you spot problems early. It lets you do your own basic maintenance like oil and filter changes. And when you do have to call a mechanic, you can tell them, “I have no water coming from my tell-tale,” instead of “My engine is making a funny noise.” That saves them diagnostic time, which saves you money.

Conclusion

That engine in your boat isn’t a magic box. It’s a collection of systems, all working together. By taking a little time to develop a basic understanding of marine engine components, you’ve taken a huge step toward becoming a more confident and capable boater. You’re no longer at the mercy of every strange sound or stutter.

You now have the foundation to look at your engine and see not just a confusing mess of wires and hoses, but a fuel system, a cooling system, an electrical system. You can start to connect symptoms to systems. That’s the key.

So, what’s next?

- Pop the Hatch: Go look at your own engine. Find the fuel filter. Find the oil dipstick. Find the alternator belt. Just put your eyes on them.

- Get Your Manual: Buy the service manual for your specific engine. It’s the best investment you’ll ever make.

- Tackle One Small Job: Next time you’re at the boat, check the oil or inspect your battery terminals. Start small.

Building a solid understanding of marine engine components is a journey, but it’s one that pays huge dividends in peace of mind, safety, and enjoyment on the water. You’ve got this.

Leave a Reply