I’ll never forget the look on a guy named Ray’s face a few years back. He’d brought in his beloved 24-foot Sea Ray for a repower, and I walked him through the quote for a new Mercruiser inboard. He just stared at the paper and finally asked, “Why are marine engines so expensive? I could buy a whole car for this price!”

He’s not wrong, and it’s a question I get almost every week in my shop near Dinner Key. It seems crazy that an engine that sits in a boat could cost two or three times as much as the one in your truck. But the truth is, they are two completely different beasts, built for two completely different worlds.

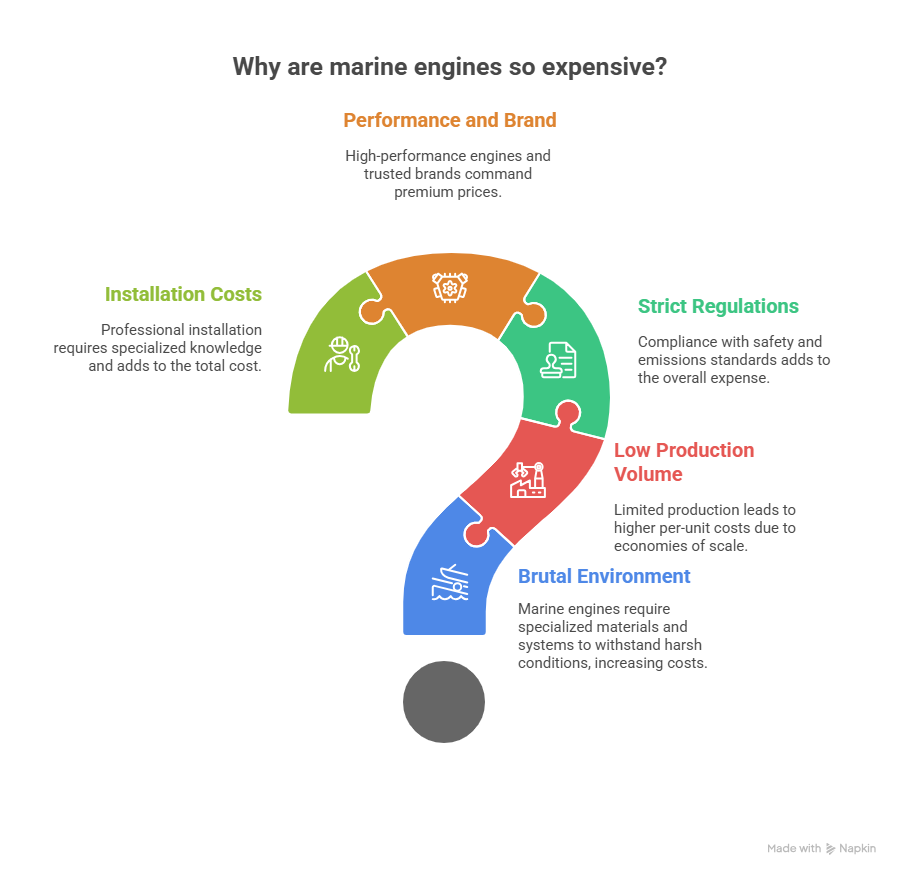

That price tag isn’t just a random number. It’s the result of brutal engineering demands, specialized materials, low production numbers, and safety features you can’t live without. So, let’s pull back the curtain. I’m going to break down for you exactly why marine engines are so expensive, from the perspective of someone who tears them down and puts them back together every day.

Table of Contents

It Starts with the Brutal Environment

First, let’s talk about where these engines live. A car engine sits in a relatively dry, protected box, running at about 20-30% of its power most of the time. It gets to cool down and rest.

A marine engine lives in a constant bar fight with saltwater, humidity, and vibration. It’s often crammed into a tight, damp space with poor airflow, and we ask it to run at high RPMs under heavy load for hours on end. It’s one of the harshest environments you can imagine for a piece of machinery. Answering “why are marine engines so expensive?” begins right here.

To survive this, they need special treatment:

- Corrosion Resistance is Everything: Manufacturers can’t use standard cast iron or steel. They use specialized alloys, stainless steel, brass, and bronze components. Even the bolts and gaskets are made of materials designed not to rust into oblivion. This stuff costs way more than standard automotive parts.

- Closed-Loop Cooling: Many inboard engines use a closed-loop cooling system, like your car’s radiator, but with a heat exchanger that uses raw seawater to cool the antifreeze. This protects the engine block from saltwater corrosion but adds complexity and cost.

- Ignition Protection: This is a huge one. Fuel vapors in an enclosed engine bay are basically a bomb waiting to go off. Marine engines have sealed alternators, starters, and distributors that are designed not to create a spark that could cause an explosion. This is a non-negotiable safety feature required by the Coast Guard, and it adds significant cost. Answering “why are marine engines so expensive?” is partly about paying for safety that keeps you from becoming a news headline.

The Numbers Game: Low Volume and High Standards

Think about how many Ford F-150s are sold each year—nearly a million. Now think about how many 30-foot Sea Rays are sold. It’s a tiny fraction of that.

This is the concept of “economies of scale,” and it’s a major reason why marine engines are so expensive.

- Low Production Volume: Engine manufacturers like Mercury, Volvo Penta, and Yamaha have to spread their research, development, and tooling costs over a much smaller number of units. Every engine has to carry a bigger piece of that financial burden, which drives up the price for you and me.

- Strict Regulations: The EPA and the Coast Guard have very strict emissions and safety standards for marine engines. Getting an engine certified is an expensive and time-consuming process involving tons of testing. Those costs are baked right into the price of the engine. Every time the regulations get tighter, the answer to “why are marine engines so expensive?” gets a little longer.

Performance, Brands, and Installation Costs

On top of the specialized engineering, you’re also paying for performance and the peace of mind that comes with a trusted brand.

To help put it in perspective, here’s a quick breakdown of how these factors play out across different engine types.

| Engine Type | Key Cost Drivers | Why It’s Expensive |

|---|---|---|

| Small Outboard (Under 50HP) | Portability, simplicity, high reliability | Still needs corrosion resistance and ignition protection. |

| High-Performance Outboard (300HP+) | Advanced tech (VVT, direct injection), power-to-weight ratio | Enormous R&D costs, complex electronics, premium materials. |

| Gas Inboard/Sterndrive | Automotive-based but heavily marinized, cooling systems | Complete re-engineering of an auto block for marine duty. |

| Diesel Inboard | High torque, extreme durability, fuel efficiency | Built for commercial-grade longevity, heavy-duty components. |

You’re not just buying horsepower; you’re buying the reliability to get you home from 30 miles offshore. Brands like Yamaha and Mercury have spent decades building a reputation for engines that don’t quit. That reputation is part of the price. This is a key part of understanding why marine engines are so expensive.

Finally, you can’t just drop a marine engine in like you would in a car. Installation is a specialized job that requires knowledge of alignment, plumbing, and electrical systems. A professional installation can add thousands to the final bill, but it’s crucial for safety and performance. This labor component is another factor in “why are marine engines so expensive?” from start to finish.

The Cost Doesn’t Stop at the Sale

So, why are marine engines so expensive even after you own one? Because the parts and service are specialized, too. You can’t run down to the local auto parts store and grab a new water pump for your Volvo Penta. Marine-specific parts are made in lower volumes and cost more.

The mechanics who work on them also need specialized training. My hourly rate of $150 reflects years of experience and investment in tools that are specific to marine work. This specialized labor market is another piece of the puzzle of why marine engines are so expensive to maintain.

FAQ: Questions I Get Asked All the Time

Is it cheaper to rebuild my marine engine?

Sometimes. If the core block is in good shape, a rebuild can save you thousands compared to a new engine. But if you have significant corrosion or a cracked block, it’s often more cost-effective to replace it.

Why do parts for my outboard cost so much more than for my car?

Low volume, again. And the materials are better. A marine water pump impeller has to survive in salt and sand. A car’s water pump doesn’t. That quality difference has a price.

Can I use automotive parts on my boat engine?

Absolutely not. Especially not electrical parts like the alternator or starter. It’s incredibly dangerous due to the risk of sparks and fire. This is a critical safety issue that helps explain why marine engines are so expensive.

How can I save money on maintenance?

Do the simple stuff yourself. Learn to change the oil, gear lube, and spark plugs. But most importantly, be religious about flushing your engine with fresh water. It’s the cheapest insurance you can buy.

Is the high price of a new engine really worth it?

If you value reliability, safety, and modern fuel efficiency, then yes. A new engine comes with a warranty and the peace of mind of knowing you have the latest technology pushing you across the water.

The Bottom Line

So, why are marine engines so expensive? Because they are not car engines. They are highly specialized pieces of equipment, designed and built to survive in one of the most hostile environments on earth while performing a very demanding job.

From the corrosion-resistant metals and explosion-proof electronics to the low production volumes and specialized labor, every step of the process adds cost. But it also adds reliability and safety. And when you’re miles from shore with your family, that’s a price worth paying.

Author Bio

I’m Alex, a 15-year marine technician in South Florida, ABYC-certified. I’ve diagnosed, rebuilt, and repowered hundreds of gas and diesel marine engines. I know firsthand why marine engines are so expensive because I work on the complex systems that justify that cost every single day at my shop near Dinner Key.

Leave a Reply