I’ve been wrenching on boats in South Florida for 15 years, and if there’s one thing I’ve learned, it’s that zinc anodes for boats are the unsung heroes of keeping your vessel safe from galvanic corrosion. I started helping my dad bolt zinc anodes for boats onto hulls in our Fort Lauderdale garage back in 2009, and now I service boats at marinas like Dinner Key and Bahia Mar. Last June 2024, a client named Javier brought his Sea Ray 350 to my shop at Coconut Grove, panicking about a $2,500 prop repair. Turns out, his zinc anodes for boats were shot—completely eroded, leaving his underwater metals exposed. Here’s my guide to mastering zinc anodes for boats, so you don’t end up with a repair bill that makes you wince.

Table of Contents

What Are Zinc Anodes for Boats and Why Do They Matter?

Zinc anodes for boats are small metal blocks designed to corrode so your expensive underwater parts—like props, shafts, and rudders—don’t. They’re your boat’s bodyguards, taking the hit from galvanic corrosion, an electrical process where saltwater acts like a battery, eating away at less noble metals. Without zinc anodes for boats, you’re looking at thousands in repairs. I’ve seen a guy at Key Biscayne lose a $3,000 bronze prop because his anodes weren’t checked. This guide covers how zinc anodes for boats work, how to pick the right ones, and how to maintain them to keep your boat safe.

How Do Zinc Anodes for Boats Stop Corrosion?

When your boat’s in saltwater, metals like bronze props and stainless shafts create a tiny electrical current. The less noble metal corrodes first, and that’s where zinc anodes for boats come in—they’re less noble than anything else on your hull, so they sacrifice themselves. I learned this from an old mechanic named Ray in 2010, who showed me a rusted-out rudder from a neglected yacht. For zinc anodes for boats to work, they need a solid electrical bond—bare metal contact is non-negotiable. Paint or gunk on the mounting surface? Your anode’s useless.

Why South Florida’s Saltwater Makes Anodes Critical

Miami’s humid, salty marinas—like Stiltsville or Bahia Mar—accelerate corrosion. I’ve seen zinc anodes for boats disappear in six months in “hot” marinas with stray currents from nearby boats. Regular checks are a must here. If you’re boating in South Florida, zinc anodes for boats are your first defense against the salty Atlantic eating your hull.

How Do I Choose the Right Zinc Anodes for Boats?

Picking the right zinc anodes for boats isn’t about grabbing the cheapest option at West Marine. Material, shape, and quality matter, and getting it wrong can cost you big.

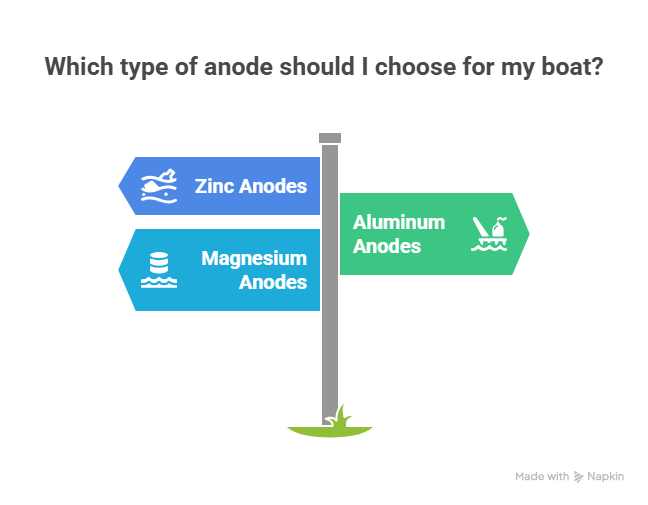

Matching Anode Material to Water Type

In saltwater, zinc anodes for boats are the go-to because they corrode steadily in high-conductivity saline water. For brackish water—like parts of the Intracoastal—I recommend aluminum anodes, which work in both brackish and saltwater. Never use magnesium in saltwater; it’ll dissolve in weeks, as I saw with a client’s Boston Whaler last summer. Here’s my cheat sheet:

- Saltwater: Zinc anodes for boats or aluminum.

- Brackish: Aluminum.

- Freshwater: Magnesium only.

Getting the Shape and Size Right

Anodes come in shapes for specific parts—hull plates, shaft collars, rudder anodes, or prop nut anodes. I always check the manufacturer’s specs for my clients’ boats, like the Sea Ray 350 I fixed last June. Using the wrong size messes with hydrodynamics and protection. For example, a shaft anode that’s too small won’t shield a long prop shaft.

Why Quality Matters for Zinc Anodes

Cheap anodes can “passivate,” forming a crust that stops them from working. I learned this the hard way in 2012 when a client’s “bargain” anode failed, costing him a $1,500 rudder repair. Always buy Mil-Spec A-18001K or ASTM B418 Type I zinc anodes for boats to ensure purity. I get mine from a trusted supplier in Fort Lauderdale—worth every penny.

Table: Anode Materials for Different Waters

I put this table together from jobs I’ve done in South Florida:

| Material | Water Type | Lifespan | Best Use Case |

|---|---|---|---|

| Zinc | Saltwater | 6–12 months | Coastal marinas (e.g., Bahia Mar) |

| Aluminum | Brackish/Saltwater | 8–14 months | Intracoastal, mixed waters |

| Magnesium | Freshwater ONLY | 12–18 months | Lakes, never saltwater |

How Do I Replace Zinc Anodes for Boats?

Swapping zinc anodes for boats is a DIY job if you’re handy, and it’s satisfying to know you’re protecting your boat. Here’s my process, honed over years in Miami marinas.

Tools and Prep

Before hauling out, snap photos of every anode’s location—hull, shaft, rudder, trim tabs. I did this for a client’s Grady-White last month and caught a hidden anode on the trim tab. You’ll need:

- Socket or wrench set for anode bolts.

- Wire brush (a drill-mounted wire wheel is faster).

- Certified zinc anodes for boats.

- Penetrating oil for seized bolts.

Step 1: Remove Old Anodes

Locate all anodes and loosen their bolts. Some fight back—saltwater’s brutal on fasteners. I had to soak a rusted bolt on a client’s Bayliner with penetrating oil last July. Be patient; don’t strip the bolts.

Step 2: Clean the Mounting Surface

This is the step most folks rush, and it’s the most critical. Scour the mounting surface to bare, shiny metal with your wire brush. I spent 10 minutes cleaning a hull anode mount for a client at Stiltsville—made all the difference. Never paint this surface; paint kills the electrical bond.

Step 3: Install New Anodes

Bolt the new zinc anode for boats onto the clean surface, ensuring no gaps. Tighten evenly, following torque specs if provided. For engine anodes, use the new gaskets in the kit. A tight, clean bond means your anode’s ready to protect.

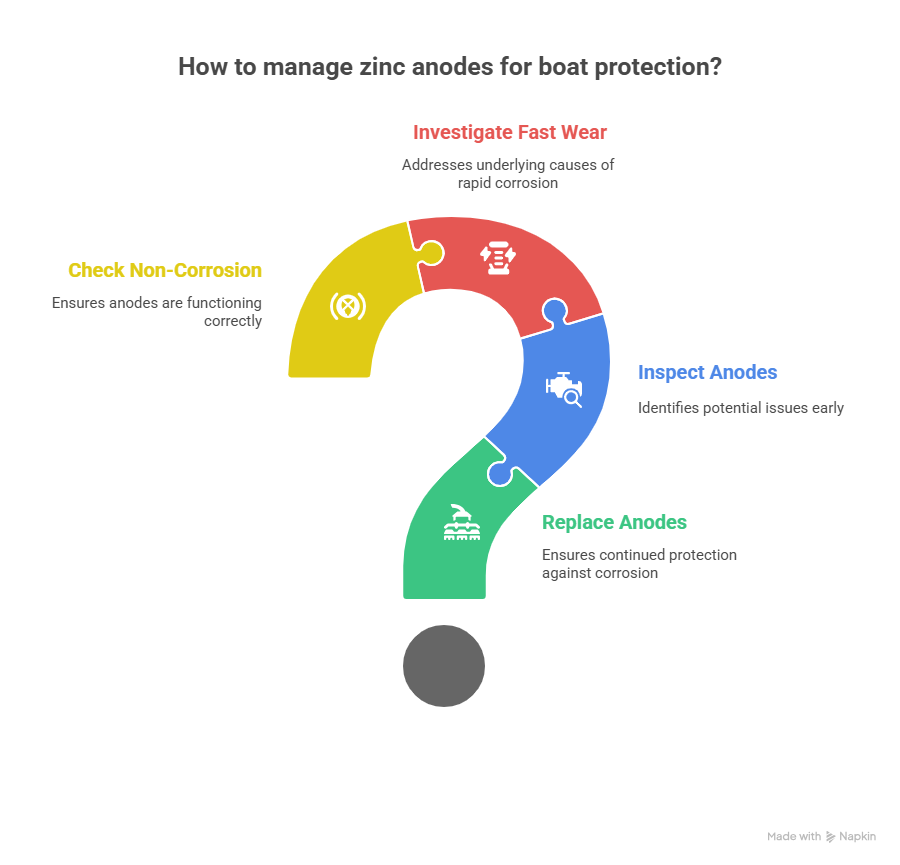

When Should I Inspect and Replace Zinc Anodes?

Timing’s everything with zinc anodes for boats. The “50% rule” is my golden standard—replace any anode that’s 50% eroded. A half-gone anode can’t generate enough current to protect your hull. I saw a client’s prop shaft take $2,000 in damage because he waited too long.

Annual Inspections

Check anodes every haul-out, at least once a year. In Miami’s salty marinas, shaft anodes might need replacing every season. I keep a logbook for my Boston Whaler, noting replacement dates and anode conditions—it’s saved me headaches.

Watch for “Hot” Marinas

Marinas like those near steel pilings in Fort Lauderdale can burn through anodes faster. I check mid-season if I’m docked in a hot spot. A quick dive or haul-out can catch issues early.

Why Are My Zinc Anodes Wearing Out Too Fast?

Fast anode wear screams trouble. Here’s what I look for:

- Stray Current: A fault in your boat’s wiring or a neighbor’s can dissolve anodes in months. I saw this at Dinner Key last summer—$3,000 in damage.

- Wrong Material: Magnesium in saltwater vanishes fast. Stick to zinc anodes for boats in saline waters.

- Hot Marina: Steel structures nearby overwork anodes.

If anodes vanish quickly, call an ABYC-certified marine electrician for a corrosion survey. I referred a client to one in 2023, and they found a stray current issue in 20 minutes.

Why Aren’t My Zinc Anodes Corroding at All?

An anode that looks new after a year isn’t working—it’s a dead giveaway something’s wrong. Common issues:

- Bad Contact: A dirty mounting surface blocks the electrical bond. I caught this on a client’s Sea Ray in 2024—cleaned it to bare metal, problem solved.

- Passivated Anodes: Cheap anodes crust over. Stick to Mil-Spec zinc anodes for boats.

- Broken Bonding: A corroded bonding wire breaks the circuit.

Non-corroding anodes are as bad as none. Check connections and quality immediately.

FAQ: Zinc Anodes for Boats

What do zinc anodes for boats do?

Zinc anodes for boats corrode to protect your underwater metals, like props and shafts, from galvanic corrosion in saltwater. They’re less noble, so they take the hit. I’ve seen a $2,000 prop saved by a $20 anode. Check them yearly.

How often should I replace zinc anodes for boats?

Replace any anode that’s 50% eroded—usually every 6–12 months in saltwater. I check mine at every haul-out, logging wear patterns. In Miami, shaft anodes might need swapping every season.

Can I use zinc anodes for boats in freshwater?

No, zinc anodes for boats are for saltwater. Use magnesium for freshwater—it’s more active. I saw a guy’s magnesium anode dissolve in two weeks in saltwater—$1,500 mistake. Stick to zinc in saline waters.

Why are my zinc anodes disappearing so fast?

Rapid wear means stray current, wrong material, or a “hot” marina. I had a client at Bahia Mar lose anodes in three months due to stray current—needed an electrician’s survey. Check your wiring ASAP.

Why aren’t my zinc anodes corroding?

Non-corroding anodes aren’t protecting—likely a dirty mounting surface or cheap, passivated anodes. I fixed this for a Sea Ray owner by cleaning to bare metal. Always use Mil-Spec zinc anodes for boats.

How do I install zinc anodes for boats correctly?

Clean the mounting surface to bare, shiny metal, then bolt the anode securely. I spent 10 minutes scouring a client’s hull anode mount last month—key to a good bond. Never paint the contact point.

Where can I buy quality zinc anodes for boats?

Get Mil-Spec or ASTM-certified zinc anodes from marine suppliers like West Marine or local shops in Fort Lauderdale. I’ve used a trusted supplier for years—$30 well spent to avoid a $2,000 repair.

Conclusion: Protect Your Boat with Zinc Anodes

Zinc anodes for boats aren’t just maintenance—they’re your hull’s lifeline against galvanic corrosion. I’ve seen too many boaters at Dinner Key or Stiltsville pay thousands for repairs that a $20 anode could’ve prevented. Follow the 50% rule, match zinc anodes to saltwater, clean mounting surfaces to bare metal, and buy Mil-Spec quality. Before your next haul-out, snap photos of your anodes and grab a wire brush. This simple habit keeps your boat safe and your wallet happy.

Author Bio

I’m Alex, a 15-year marine technician with ABYC certification, servicing boats across Miami and Fort Lauderdale. I’ve installed hundreds of zinc anodes for boats, from Sea Rays to Boston Whalers, saving clients thousands in corrosion repairs.

Leave a Reply