What Is Boat Engine Cooling and Why Does It Matter?

Boat engine cooling is the lifeline of marine engines, ensuring they don’t overheat during operation. Whether it’s an inboard engine or an outboard, marine diesel engines or gasoline-powered ones, excessive heat can damage the engine block, cylinder head, and key components, leading to costly repairs. This guide answers your burning questions about boat engine cooling, covering how it works, its components, and maintenance tips for optimal performance. From raw water systems to closed-loop cooling systems, we’ll explore marine cooling solutions to keep your boating experience smooth—backed by insights from boat engine manufacturers and marine solutions experts.

[BUTTON: Explore Boat Engine Cooling Solutions]

Visit Cooling System Marine Engine.

How Much Does Boat Engine Cooling Maintenance Cost?

Typical Costs for Cooling System Upkeep

| Task | Average Cost | Range |

|---|---|---|

| Coolant Replacement | $50 | $30 – $70 |

| Water Pump Impeller Swap | $100 | $80 – $150 |

| Heat Exchanger Cleaning | $200 | $150 – $300+ |

Maintaining boat engine cooling varies by task—replacing marine coolant products or a rubber impeller for the raw water pump is affordable, while servicing oil coolers or heat exchangers for powerful engines costs more. Boat owners can expect these expenses annually for optimal performance—check Boat Maintenance Miami for local rates.

Professional Service Costs

| Service | Average Hourly Rate | Range |

|---|---|---|

| Marine Diesel Mechanic | $90/hr | $70 – $120/hr |

Hiring a pro from Marine Diesel Repairs ensures thorough anode replacement and exhaust manifold care, critical for marine vessel health.

- Diesel Engine Rebuilders: Your Guide to Marine Engine Maintenance and Repair

- Marine Diesel Specialist: Frequently Asked Questions

- Diesel Marine Mechanic Salary: A Comprehensive Guide

What Are the Main Types of Boat Engine Cooling Systems?

Raw Water Cooling Explained

Raw water cooling uses cooler water—raw saltwater or fresh water—from the boat’s environment, pumped through the engine block via a raw water pump. This simple rule suits smaller boats in shallow waters but risks corrosive scale buildup, reducing engine efficiency over time—see Raw Water Pump Replacement.

Closed-Loop Cooling Systems Unveiled

Closed cooling employs a heat exchanger jacket and engine coolant in a closed-loop cooling system, circulating fresh water through the engine compartment. Boat engine manufacturers favor this for marine diesel engines, as it prevents corrosion scale and boosts engine performance—ideal for boating conditions requiring efficient cooling.

Air-Cooled vs. Water-Cooled Outboards

Air-cooled engines, like Briggs and Stratton models, rely on air flow, while water-cooled systems dominate modern boats. Air-cooled outboard motor functions are rare today, overshadowed by marine quality bronze water pumps—learn more at Boat Engine Cooling System.

How Does Boat Engine Cooling Work?

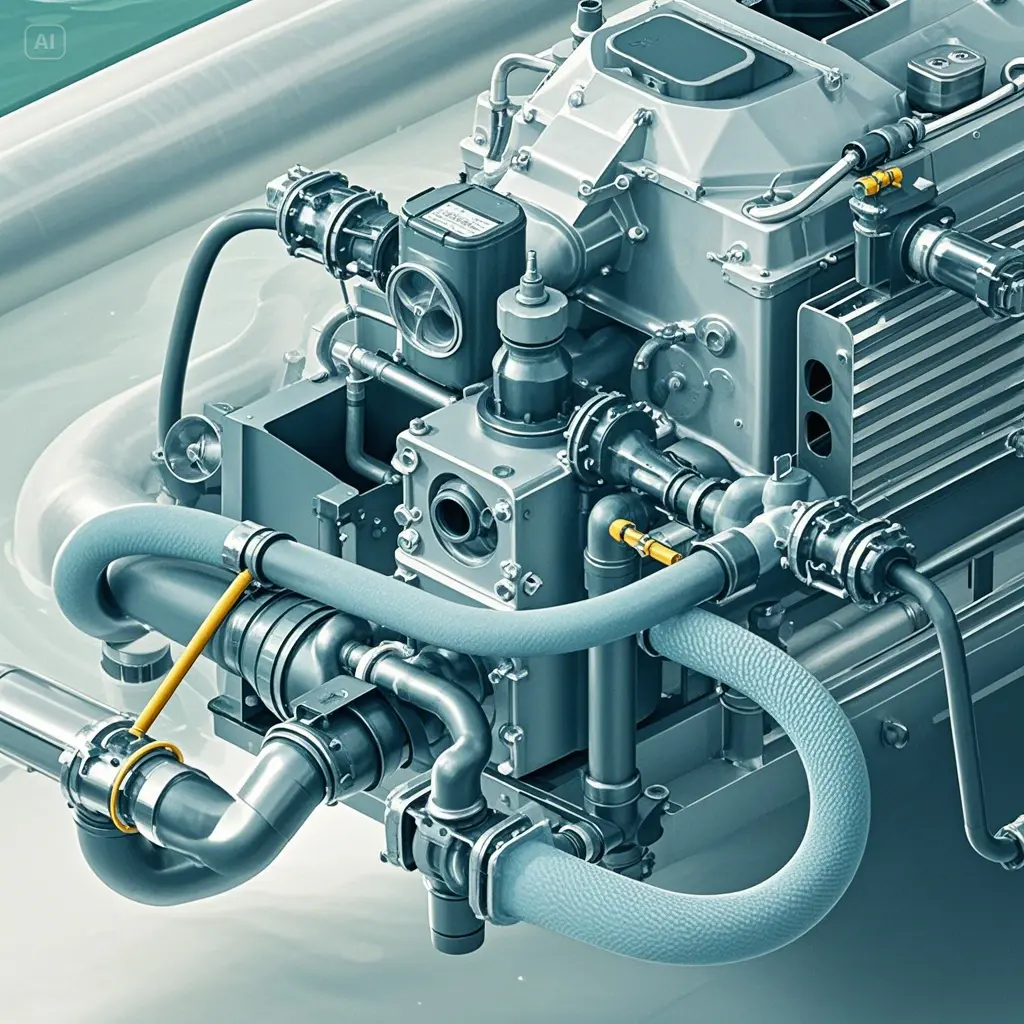

The Cooling Process Step-by-Step

- Intake: Raw water systems draw cool water through a raw water filter, while closed systems use a 50-50 mixture of coolant and water.

- Circulation: A water pump impeller pushes water via drive belts through the engine water jacket and cylinder head.

- Heat Transfer: Heat exchangers or series of heat exchangers swap waste heat with raw water, cooling the entire engine.

- Expulsion: Exhaust gases mix with heated water, exiting via the exhaust exit—see Marine Exhaust System.

This cycle prevents engine damage, maintaining engine temperature for optimal performance—key for boating excursions.

Key Components Involved

Hose Clips: Secure convoluted hoses to avoid leaks.inspect hoses and fittings can lead to leaks and overheating issues.

Thermostat Housing: Regulates water flow—check it regularly.

Oil Coolers: Manage heat in marine diesel engines—serviced via Marine Engine Oil Change.

What Maintenance Does Boat Engine Cooling Require?

Essential Regular Checks

Boat owners must perform regular basis checks on boat engine cooling:

- Inspect water hoses and hose clips for wear—replace via Boat Parts Accessories.

- Monitor engine hour logs to schedule anode replacement—keep corrosion at bay.

- Flush heat exchanger deals with raw saltwater buildup every season—expert research teams recommend this for marine vessels.

Coolant and Impeller Tips

Use boat antifreeze over automotive type antifreeze for marine solutions—swap every two years to avoid engine compartment corrosion. Replace the water pump impeller annually to ensure water quality and efficient cooling—order from Boat Motor Mount Repair.

How Can I Troubleshoot Boat Engine Cooling Problems?

Common Issues and Fixes

- Overheating: Check for raw water-cooled engines’ blockages or a faulty thermostat housing—fix with Boat Engine Diagnostics.

- Low Water Flow: Inspect the air filter and keel cooler for clogs—clear them out.

- Corrosive Scale: Use marine coolant products to combat saltwater boating environments’ effects—technical teams suggest Marine Diesel Engine Maintenance.

Boat engine breakdowns from poor cooling can ruin a boating experience—stay proactive.

Signs of Trouble

- Rising engine temperature on gauges.

- Reduced exhaust level water output.

- Unusual noises from drive belts or pumps.

Why Should I Care About Boat Engine Cooling Maintenance?

Neglecting boat engine cooling risks engine owner woes—terms of engine horsepower drop, and boat engine types suffer from engine damage over periods of time. A closed-loop cooling system or raw water cooling, if maintained, ensures marine engines last, saving vessel owners from costly repairs—see Yanmar Rebuild for rebuild insights.

[BUTTON: Get Expert Boat Engine Cooling Help]

Contact Diesel Marine Mechanic.

Conclusion

Mastering boat engine cooling is vital for boat motor health—whether it’s air-cooled and water-cooled outboard engines or inboard engine setups, regular checks and marine cooling systems keep your boating community safe. From the engine block to exhaust components, understanding how cool water flows prevents corrosive scale and ensures engine efficiency. Invest time in boat engine cooling maintenance for a reliable boating excursion—your marine vessel deserves it.